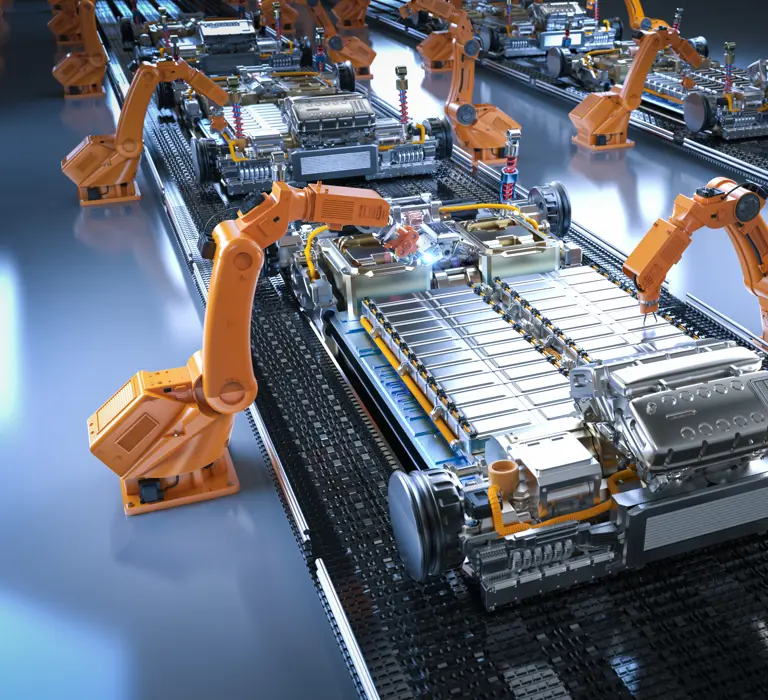

At the core of an electric vehicle lies its most crucial, substantial, and costly component, the battery. Despite its paramount importance, there exists a prevalent misunderstanding among many of us regarding the intricate processes involved in crafting these essential power sources and the diverse materials that constitute them.

Electric vehicle batteries, being the linchpin of their functionality, demand a deeper understanding of their construction and composition. Often underestimated in complexity, these powerhouses are not merely a single entity but a sophisticated amalgamation of various materials and technologies working in unison.

The seemingly straightforward assumption that a lithium-ion battery is solely comprised of lithium tells only part of the story. While it is accurate that lithium is a vital component, the intricate design of a lithium-ion battery involves a nuanced interplay of diverse materials to optimise functionality, safety, and overall efficiency.

The Science Part

The basic structure of a lithium-ion battery comprises three main components: a positive electrode (cathode), a negative electrode (anode), and an electrolyte. The cathode typically contains lithium, cobalt, manganese, or iron oxide, depending on the specific chemistry of the battery. Popular cathode materials include lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), and lithium iron phosphate (LiFePO4).

The anode, on the other hand, is commonly made of graphite, which acts as a host for lithium ions during the charging and discharging cycles. Graphite anodes are preferred for their stability and ability to intercalate lithium ions efficiently.

As for the electrolyte, it is typically a lithium salt dissolved in a solvent, forming a conductive medium for lithium ions to move between the cathode and anode during the electrochemical reactions. Commonly used electrolytes include lithium hexafluorophosphate (LiPF6) in a mixture of organic solvents.

In addition to these primary components, electric car batteries also feature separators to prevent the electrodes from coming into direct contact, ensuring the prevention of short circuits. The casing of the battery is typically made from materials that are lightweight, durable, and heat-resistant, often composed of metals like aluminium or alloys.

As you can see from the table below Lithium is far from the most used mineral compound in an EV Battery.

Average Electric Car Battery Mineral Content

|

Graphite |

28.1% |

|

Aluminum |

18.9% |

|

Nickel |

15.7% |

|

Copper |

10.8% |

|

Steel |

10.8% |

|

Manganese |

5.4% |

|

Cobalt |

4.3% |

|

Lithium |

3.2% |

|

Iron |

2.7% |

Advancements in battery technology continue to drive research into alternative materials, such as solid-state electrolytes and different cathode and anode materials, aiming to improve energy density, safety, and environmental sustainability.

This shortly could revolutionise the battery industry and push electric cars even further towards dominating the future of direction of the car industry.

In summary, while lithium is a fundamental element in electric car batteries, its composition encompasses a variety of materials to create a sophisticated and efficient energy storage system, contributing to the overall performance and viability of electric vehicles.

Get in touch with us today Our friendly team are here to help.

What our customers say...

Tom was super-helpful to deal with and very knowledgeable about the cars features. He gave good advice to allow me to make a very informed decision. Excellent person to deal with.

Date of experience: 29 May 2025

Very prompt, easy and quick! Thankfully to Charne Headech,the consultant with I spoke,all my questions was answered and soon I will receive my new car!

Date of experience: 14 April 2025

I had not leased a car before and was very impressed with Tom Glen. Tom kept me informed throughout the whole process and answered all my questions.I could have got a slightly better deal elsewhere but felt that Tom deserved the business as people buy off people. I would have no problem in recommending Tom to anyone who is looking at leasing a car.

Date of experience: 05 June 2025